What is an HVLP Spray Gun?

If you’re looking for an efficient spray gun that’s affordable and built to last, an HVLP spray gun might be right for you. Keep reading to learn more about these spray guns and what they can do for your finishing process.

HVLP = high volume, low pressure

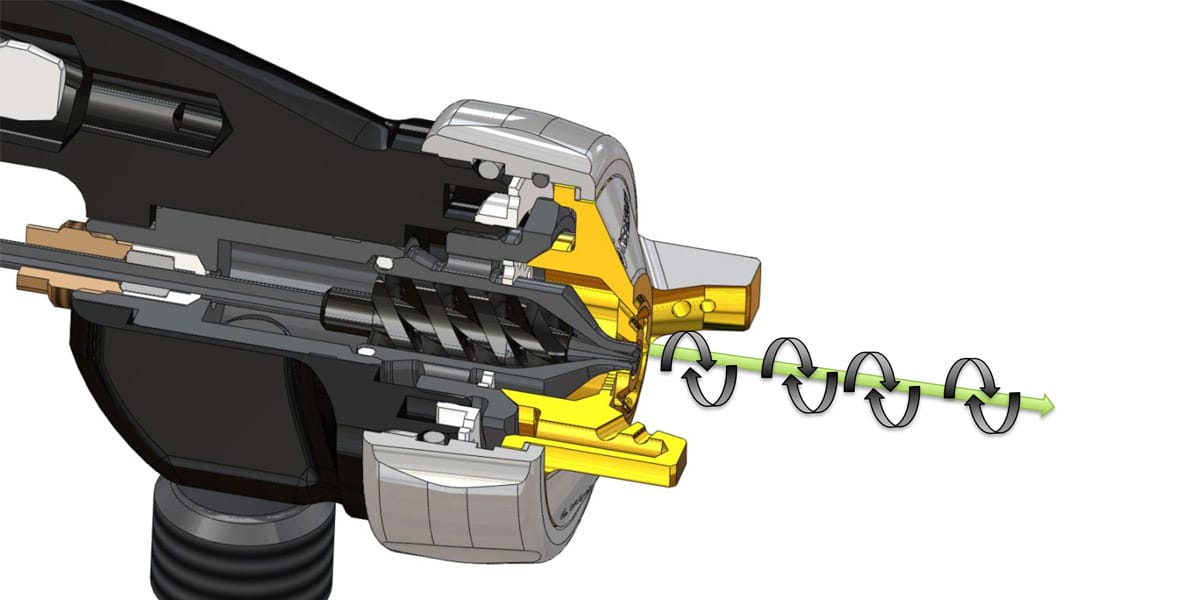

High volume low pressure (HVLP) spray guns are similar to typical spray guns in that they use a compressor to move air through the gun, but unlike regular spray guns, HVLP spray guns distribute a higher volume of air at a lower pressure.

Two types of HVLP systems

There are two kinds of HVLP spray gun systems.

Dedicated systems, which use a turbine to atomize the finish.

-

- Pros: Portable and affordable

- Cons: Limited versatility

Conversion systems, which move high-pressure air from a compressor to a lower pressure to provide more controlled spray.

-

- Pros: Functional with different types of spray guns

- Cons: Higher upfront costs, and not portable

What are the benefits of HVLP spray guns?

Since a standard spray gun emits sprays at higher pressure, they produce much more overspray in comparison to HVLP systems. On top of wasting product, overspray can also cause subpar application of finishes. HVLP spray offers finer, more efficient application and smoother finishes.

Is an HVLP spray gun right for me?

An HVLP spray gun could be ideal for you depending on the coatings you typically apply. Particularly heavy or viscous finishes won’t process as smoothly and could result in peeling finishes. HVLP guns also require more air to atomize coatings than a typical spray gun paired with a compressor. If you need portability and use fairly consistent finishes, HVLP spray guns could be a great tool for you.